Autonomous Water Treatment Systems and Machine Learning (NAWI I)

Background

Program Description and Modeling

include a summary of different projects here

Ultrafiltration Operation and Process Modeling

Dwindling fresh water supplies from traditional sources, along with frequent drought conditions worldwide, intensify the urgency to identify sustainable and alternative sources of drinking water. In recent years, the adoption of reverse osmosis (RO) for seawater and brackish water desalination and water reuse technologies has increased globally. Despite the promising and relatively accessible water treatment option, membrane fouling poses a significant challenge for the effective operation of RO plants treating seawater and brackish water. RO fouling degrades membrane performance by diminishing membrane permeability and subsequently requiring a higher feed pressure to achieve the same desired flux. As a result, the frequency of required chemical cleaning is increased, the membrane lifetime is shortened, and the operational expenditures swell.

Ultrafiltration (UF) has recently emerged as a promising approach for the pre-treatment of the feed that offers a variety of advantages over conventional options including sand filters and cartridge filters. UF membranes, with pore sizes ranging from 0.1 – 0.01 μm, are capable of removing particulates, colloids, microorganisms, and some dissolved organic matter (often with the help of coagulant dosing) that produces high quality permeate water. UF, primarily used for RO feed pre-treatment, is typically employed in a dead-end filtration mode with periodic backwash to remove foulants accumulated on the UF filters. This may be enhanced by optimizing the coagulant dosing of the feed and timed backwash frequency. However, UF fouling in a complex phenomenon that is influenced by a myriad of environmental factors (e.g., quality and temperature of feed, and the stochastic nature of the fouling phenomena). Therefore, developing an effective UF process control strategy would benefit from being able to describe the temporality of UF field performance along with quantification of fouling progression. Accordingly, our past work has focused on investigating the complex relationships between various UF operational variables (including coagulant dosing) and UF fouling behavior as observed under field conditions for UF treatment of RO seawater feed (Figure 1.).

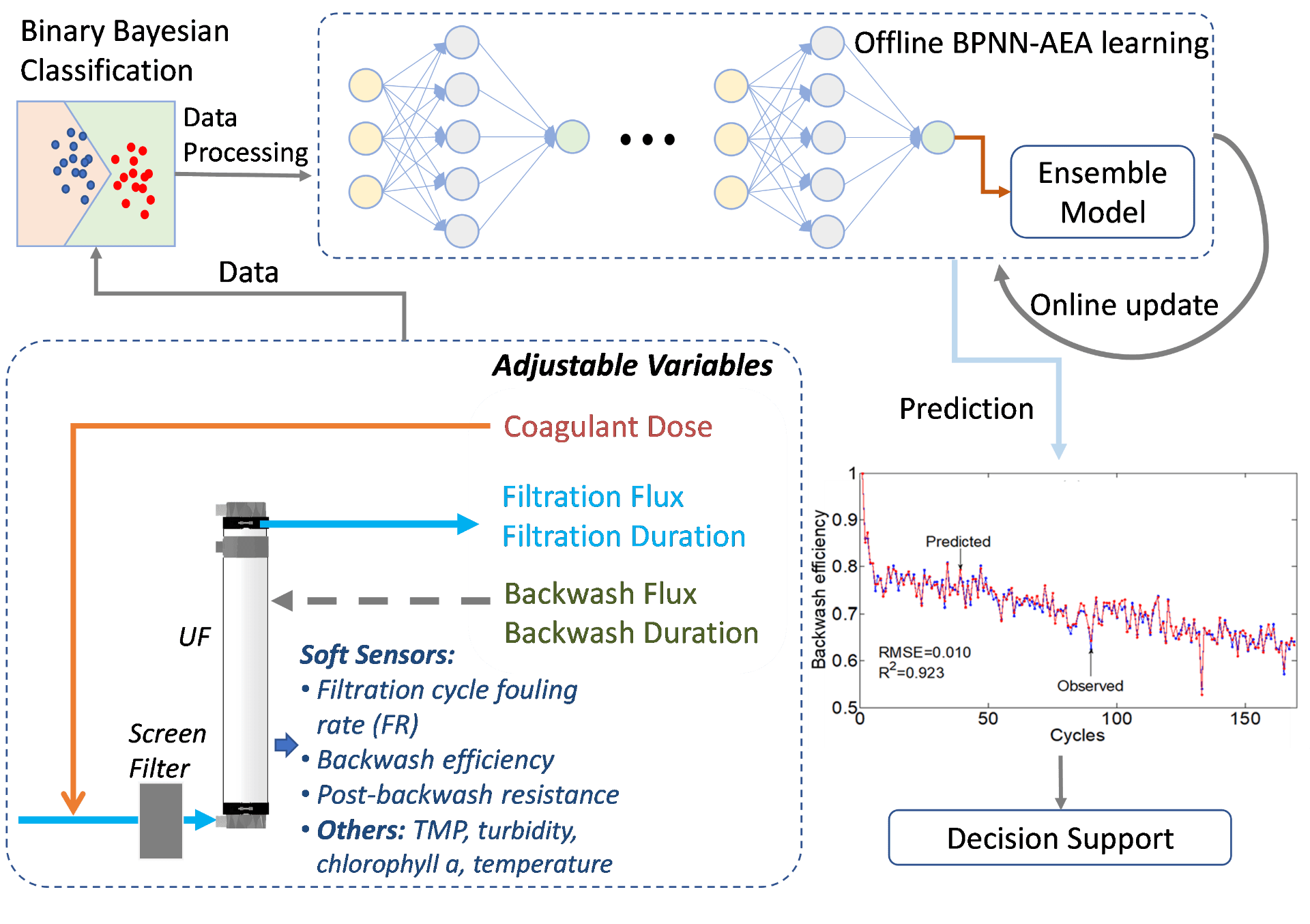

Figure 1: Graphical illustration of the approach to describing the dynamics of ultrafiltration (UF) performance in pretreatment of seawater reverse osmosis (SWRO) feedwater was explored via Ensemble Backpropagation Neural Networks (BPNN) model with Alopex Evolutionary Algorithm (AEA).

Data-driven model development for assessing UF performance in pretreatment of seawater RO feedwater:

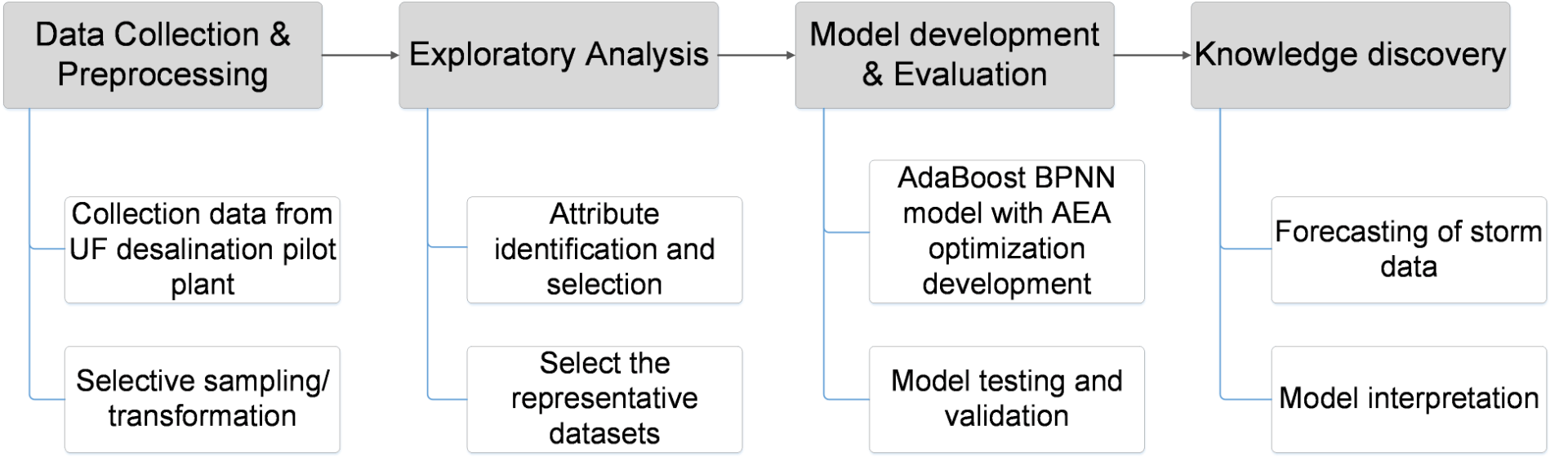

A machine learning approach to describing the dynamics of ultrafiltration (UF) performance in pretreatment of seawater reverse osmosis (SWRO) feedwater was explored via Ensemble Backpropagation Neural Networks (BPNN) model with Alopex Evolutionary Algorithm (AEA), as illustrated in Figure 2. To address data diversity challenges (i.e., bias-variance tradeoffs) for single machine learning model, an AdaBoost ensemble strategy was followed, developing a family of BPNN-AEA models for the progression of UF membrane resistance during both filtration and backwash, along with backwash efficiency of a real SWRO system with over 13 million data samples collected over the period of 422 days.

Figure 2. Workflow for UF filtration and backwash efficiency assessment and BPNN-AEA model development.

System Description:

The integrated UF/RO system had a permeate water production capacity of up to 66.8 m3/day (17,640 GPD) utilizing three 8-inch RO elements (Dow Filmtec SW30HRLE-400, The Dow Chemical Company, Midland, MI), and three inside-out polyethersulfone (PES) multi-bore hollow fiber (0.02 μm pore size) UF membrane modules (each having membrane surface area of 50 m2; Dizzer 5000 +, Inge, Greifenberg, Germany) arranged in parallel. Feed water from open sea intake was pumped directly (offshore from the port) to a 7571 L (2000 gal) holding tank (< 3 h detention time) and then delivered by a feed pump (XT100 SS, 3.73 kW, Price Pump, Sonoma, CA) controlled by a variable-frequency drive (VFD) (VLT AQUA Drive FC202, Danfoss, Denmark). Feedwater to the UF modules was first filtered via an inline basket strainer (Hayward SB Simplex, Clemmons, NC), followed by a 200 μm self-cleaning microfilter (TAF-500, Amiad Corp., Mooresville, NC). Switching between filtration and backwash mode and changing filtration/backwash directions (top or bottom) for the individual UF module banks was facilitated by electrically actuated 2 and 3 way ball valves.

UF Filtrate and backwash flowrates were monitored using magnetic flow meters (Signet 2551, George Fischer Signet, Inc. El Monte, CA) and hydraulic pressure was monitored via sensors (AST4000, American Sensor Technologies, Mt. Olive, NJ). Inline coagulant (FeCl3) dosing of the UF feed was employed at the UF pump inlet, using a metering pump (DDA 7.5-16, Grundfos, Bjerringbro, Denmark), to enhance the effectiveness of suspended matter and backwash efficiency. A turbidity meter (Signet 4150, Georg Fischer Signet LLC, El Monte, CA), fluorometer sensor (Turner Designs, Cyclops-7 2108, San Jose, CA), pH meter (Sensorex S8000CD, EM802/pH, Garden Grove, CA), and a temperature sensor (Signet 2350-3, George Fischer Signet LLC, El Monte, CA) were installed on the UF filtrate line.

Results and discussion:

System performance, with respect to the evolution of post-backwash UF resistance and backwash efficiency, was evaluated under both normal and atypical conditions (i.e., 6 days of storm event). Model performance, for UF membrane resistance and backwash efficiency, evaluated over a wide range of operating conditions and coagulant dosing strategies, revealed excellent performance even for cases of temporally variable water quality (i.e., R2 within the ranges of {0.9 – 0.946} and {0.91 – 0.972} for post-backwash resistance and backwash efficiency, respectively). Additionally, due to the availability of data for both normal and atypical operating conditions, the ensemble BPNN-AEA models were accompanied by a Bayesian classification approach to automatically recognize filtration and backwash modes provided as prior knowledge. The level of performance attained with the current machine learning modeling approach, which is particularly suited for handling the dynamics of UF operation, should prove useful for (a) determining UF performance deviation from intended baseline performance, (b) forecasting expected performance due to anticipated changes in water quality, and (c) providing a basis for model-based control of UF operation. In particular, the model described UF performance under dynamic conditions of variable coagulant dosing strategy. The excellent level of model performance suggests that there is potential for practical applications of the present machine-learning modeling approach to: (a) assess UF system performance drift such as deviation from expected baseline performance, (b) utilization of the approach for forecasting system performance based on expected changes in water quality, and (c) as a basis for model-based control of UF coagulant dosing control.

Figure 3: BPNN-AEA model (with binary Bayesian classification) prediction of UF resistance (for filtration and backwash operational modes) for the trace of the first 10 cycles in the 142 cycle

Figure 4: BPNN-AEA model (with binary Bayesian classification) predictions of UF resistance (for both the filtration and backwash operational modes) under typical operating conditions over a period of 3 days comprising of 142 UF filtration cycles (Dataset #TE10). The vertical dashed line represents the separation between the UF filtration (right) and backwash processes. (Note: turbidity, and Chlorophyll ranges were 3.4 – 5.1 NTU and 61 – 124 μg/L respectively, with UF operation at a constant coagulant dose of 2.7 mg/L Fe3+).

Distributed Water Systems Water Use Patterns in Small Communities

Small communities with impaired local well water and lack of a feasible connection to a centralized water system can potentially opt for wellhead water treatment as a mid – or long – term solution to providing safe drinking water. However, sufficient data and models of high temporal resolution (hourly to seasonal variability) for forecasting small communities’ water use patterns are critical in order to establish:

- Community water system design and operational specifications

- Water storage capacity

- Water treatment system for upgrading community water quality as needed

- Handling of sanitary water

- Overall community planning (e.g., expansion and water system infrastructure upgrade).

Intermittent Operation of Wellhead RO Desalination and Water Purification System

Transfer Learning for Updated Operational Model for Upgraded System Components

Transfer Learning for Accelerating Operational Model Development for Distributed Water Systems

Assessment of Membrane Fouling and Mineral Scaling based

Determination of Fundamental

include a summary of different projects here