Technoeconomic Evaluation of Wellhead DSWT Systems

Background

Under the pressure of an increasing global water scarcity, disadvantaged communities (DACs) are often challenged with technical, infrastructural, and financial resources to treat available local groundwater to potable water standards. While wellhead membrane-based nitrate removal and salinity reduction is feasible, small DACs lack the technical expertise to operate and manage water treatment systems, particularly when confronted with with temporal variability of water quality and community water use patterns.

Thus, it is critical that water treatment systems are autonomous (i.e., “smart”) with advanced self-adaptive operation, remote monitoring, and supervision. Accordingly, the Salinas Valley project developed and deployed three configurations of a flexible reverse osmosis (FLERO) water treatment system (capacity of 2,500 – 4,500 gallons/day). These distributed smart water treatment (DSWT) systems benefitted from expert operators that were remotely located with tools afforded via real-time cloud computing, online and remote system monitoring, and advanced supervisory control to ensure adherence to regulatory water quality.

Nevertheless, the DSWT systems must be technically and economically viable to be embraced as a permanent solution for impacted communities. Therefore, a technoeconomic assessment of the high-recovery membrane-based FLERO systems was conducted to evaluate the (1) reliability of the fully autonomous process design, (2) levelized cost of fabricating, deploying, and operating the systems, and (3) utility of modern advances in wireless communication, cloud-based data management, and “live” user/operator interfaces.

An analysis of high-resolution yearlong performance data for each system found that the FLERO system effectively self-adapted to consistently remove and reduce nitrate and salinity, respectively, levels to meet state regulated drinking water standards throughout temporal water demands and water quality. Multi-year performance data for the three systems revealed that levelized cost of treated water was reasonable and affordable even for small disadvantaged communities. Moreover, having multiple systems that are remotely managed suggests that there is merit in further development of “Virtual Water District” concept for distributed water desalination and purification.

Capital and Operational Expenditures

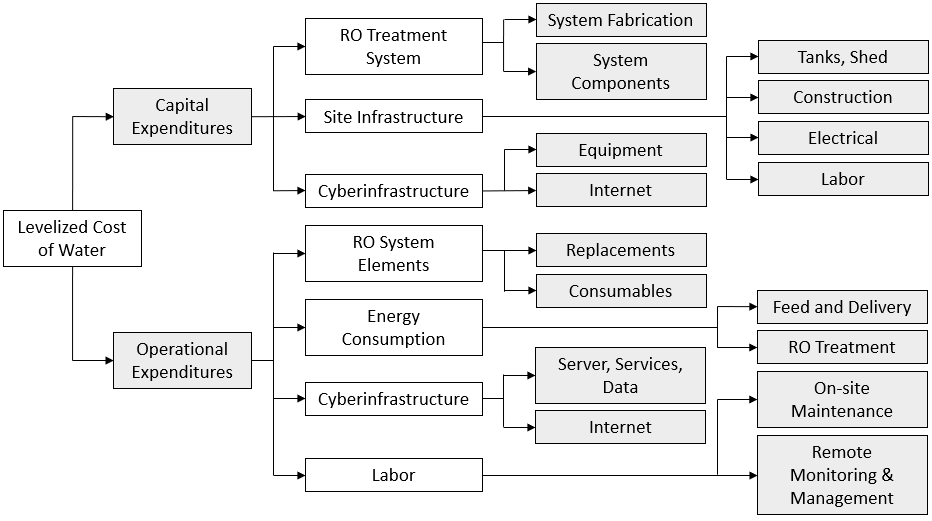

Capital expenditures (CapEx) refers to the resources that a company or organization utilizes to acquire, upgrade, or fabricate assets such as property, equipment, machinery, buildings, or technology. On the contrary, operational expenditures (OpEx) refers to costs associated with operating and/or maintaining a business/service and employing personnel. The CapEx of the three systems was composed of the fabrication of the custom RO treatment system, the site infrastructure (i.e., system enclosure, concrete slab, piping networks), and the equipment (i.e., sensors, meters, transmitters, actuators). The OpEx of the systems consisted of the chemicals and material consumed by the treatment process, energy consumption of the entire system, cyberinfrastructure services, and the labor (i.e., remote monitoring, scheduled on-site maintenance).

Figure 1. Categorized CapEx and OpEx wellhead water system costs.

Energy Consumption

The energy consumption of the treatment system was determined by the specific energy consumption (SEC), define as the energy required to produce a unit volume of delivered water. The energy consumption of the treatment system consisted of the 1. pumps utilized to collect, treat, and deliver the water, 2. supporting pumps used for the system flushing, anti-scalant injection, and chlorine dosing, and 3. system equipment (i.e., sensors, transmitters, computers). Compared to the main system pumps, the supporting pumps and system equipment consumed a negligible amount of energy. Furthermore, the SEC of each system, was found to decrease with an increase of RO module single pass recovery and with a decreased in required inlet (osmotic) pressure.

Levelized Cost of Water

The levelized cost of water (LCOW), a metric used to assess the total cost of producing water per unit volume, was derived by taking the weighted average of CapEx and OpEx for each system with respect to the individual system design capacity. Ultimately, the cost for producing 1000 gallons of potable water was $19.30 for Blue Rock, $8.40 for Santa Teresa, and $7.10 for Pryor Farms.

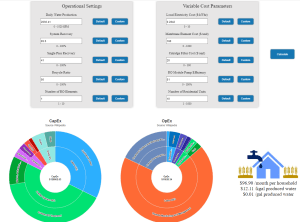

Calculator

The model utilized to conduct the technoeconomic analysis of the DSWT FLERO systems was packaged for public estimation of developing and operating similar systems with customizable settings.

Technoeconomic Calculator